When selecting activated carbon for a specific application, one key factor to consider is mesh size. Often overlooked, mesh size directly influences how effectively activated carbon performs in terms of flow rate, contact time, and contaminant removal. Whether you're purifying water, treating air, or refining chemicals, understanding mesh size can help you choose the right carbon for the job.

What is Mesh Size?

Mesh size refers to the size of the particles in a granular or powdered substance. It is typically measured in terms of the number of openings per linear inch in a screen. For example:

-

8x30 mesh means particles can pass through an 8-mesh screen but are retained by a 30-mesh screen.

-

12x40 mesh is a common size used in water treatment applications.

The higher the mesh number, the smaller the particle size.

Mesh Size Categories in Activated Carbon

-

Powdered Activated Carbon (PAC):

-

Mesh size: Typically < 80 mesh

-

Fine powder; ideal for rapid adsorption in batch or emergency treatments

-

-

Granular Activated Carbon (GAC):

-

Mesh size: Ranges from 8x30 to 12x40

-

Common in water and air filtration systems

-

-

Pelletized or Extruded Carbon:

-

Cylindrical shape; typically not measured by mesh size but by diameter (e.g., 4mm pellets)

-

Used in high-flow applications like vapor phase filtration

-

How Mesh Size Affects Performance

1. Adsorption Efficiency

-

Smaller mesh sizes (finer particles) provide more surface area and shorter diffusion paths, leading to faster adsorption.

-

Larger mesh sizes (coarser particles) may have slower adsorption rates but are better suited for longer contact time.

2. Flow Rate and Pressure Drop

-

Fine mesh sizes can restrict flow and increase pressure drop in systems.

-

Coarser mesh sizes allow for better flow characteristics, making them ideal for continuous systems.

3. Contact Time

-

Coarser mesh carbon provides longer contact time, which may improve removal efficiency for certain contaminants.

-

Finer carbon is useful when fast reactions are needed, but contact time is limited.

4. Handling and Maintenance

-

Finer carbon can create dust and be more difficult to handle, requiring additional filtration or containment.

-

Coarser granules are easier to manage in large-scale systems.

Choosing the Right Mesh Size for Your Application

| Application | Recommended Mesh Size |

|---|---|

| Drinking Water Filtration | 12x40 |

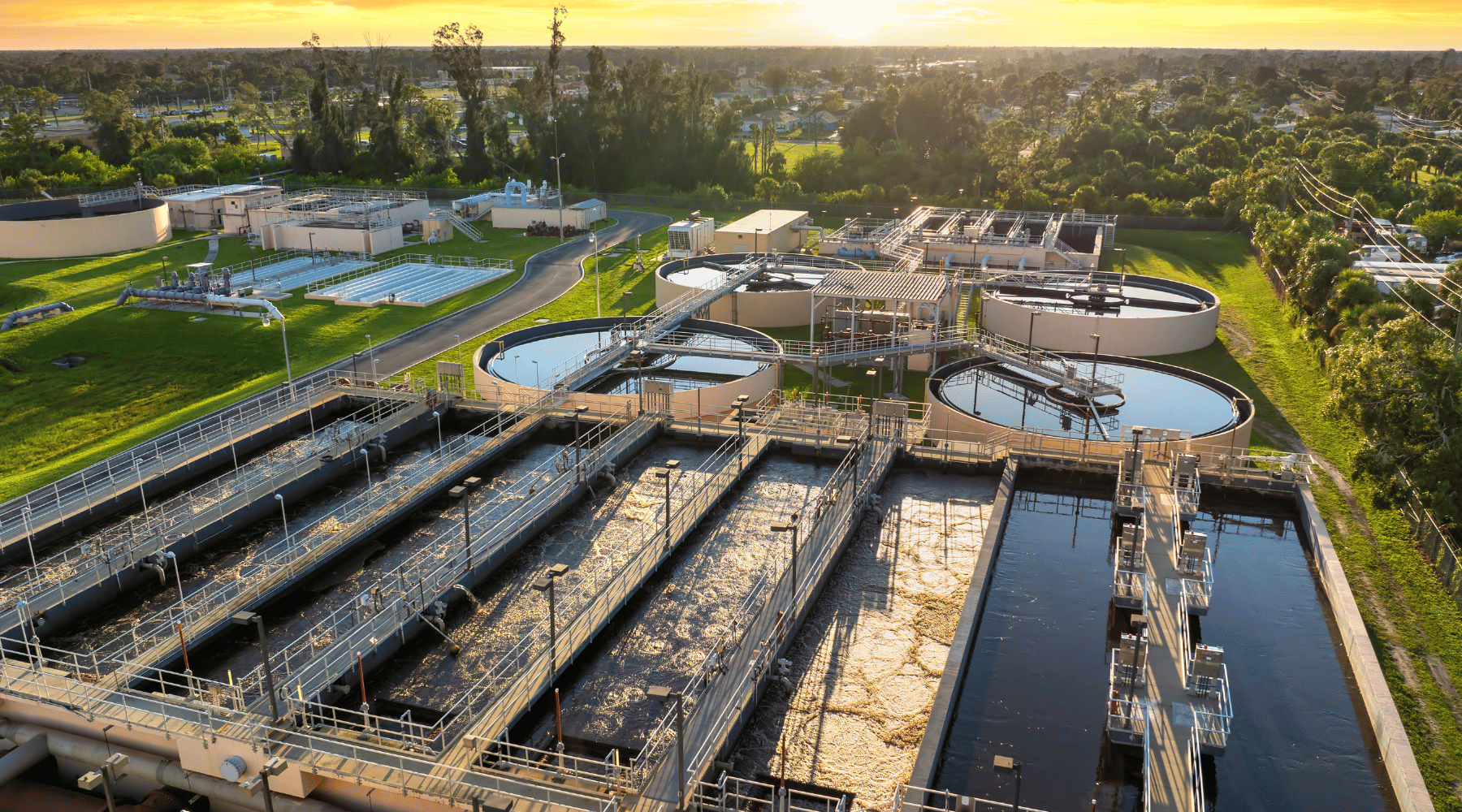

| Wastewater Treatment | 8x30 or 12x40 |

| Air and Vapor Filtration | Pelletized (4mm) |

| Emergency Spill Treatment | PAC (<80 mesh) |

| Aquariums | 8x30 or 12x40 |

| Industrial Chemical Processes | Mesh varies by compound |

Conclusion

Mesh size plays a critical role in the performance of activated carbon. It affects everything from how quickly contaminants are adsorbed to how easily fluids pass through the filtration media. By understanding the relationship between mesh size and system needs, you can make informed decisions that enhance efficiency, reduce costs, and ensure the best results for your specific application.

If you’re unsure which mesh size or carbon type is right for your filtration needs, don’t hesitate to contact us. Our team is here to help you select the most effective solution for your specific application.

- Phone: 949-229-2587

- Email: sales@activatedcarbondepot.com

- Contact Form: Click Here