The art of distillation has been practiced for centuries, producing some of the world’s finest spirits. However, achieving the desired purity and flavor profile requires more than just expert craftsmanship. Activated carbon, also known as activated charcoal, plays a crucial role in refining spirits, removing impurities, and enhancing their overall quality. This article delves into the significance of activated carbon in distilleries, its benefits, and how it can elevate the distillation process.

Understanding Activated Carbon in the Context of Distillation

Activated carbon is a highly porous material with an extensive surface area, making it ideal for adsorbing impurities. In distillation, it is commonly used to:

- Remove Unwanted Impurities: Activated carbon adsorbs compounds that can negatively impact the taste, odor, and clarity of spirits.

- Enhance Flavor Profiles: By eliminating off-flavors and harsh notes, it ensures a smoother and more refined product.

- Improve Color: Some spirits require color adjustments, which activated carbon can achieve by removing unwanted pigments or discoloration.

The Science Behind Activated Carbon’s Effectiveness

Activated carbon works through a process known as adsorption. This involves trapping impurities on its vast network of micropores and mesopores. These impurities often include:

- Fusel Oils: These higher alcohols can impart harsh flavors to spirits.

- Ethyl Carbamate: A naturally occurring compound in fermentation that can be removed for health and quality considerations.

- Volatile Organic Compounds (VOCs): Compounds that affect the aroma and taste of the spirit.

- Pigments: Unwanted color components that affect the visual appeal of the final product.

Applications of Activated Carbon in Distilleries

Activated carbon can be applied at various stages of the distillation process:

- Post-Distillation Treatment: After the spirit has been distilled, activated carbon is used to filter and polish the product, removing residual impurities.

- Water Treatment: Distilleries often use activated carbon to purify water before mixing it with the spirit. Clean water is essential to maintaining the quality of the final product.

- Aging and Maturation: During the aging process, activated carbon can be employed to fine-tune the flavor and clarity of spirits.

Choosing the Right Activated Carbon for Distilleries

Not all activated carbon is created equal. Distilleries must select the appropriate type to suit their needs:

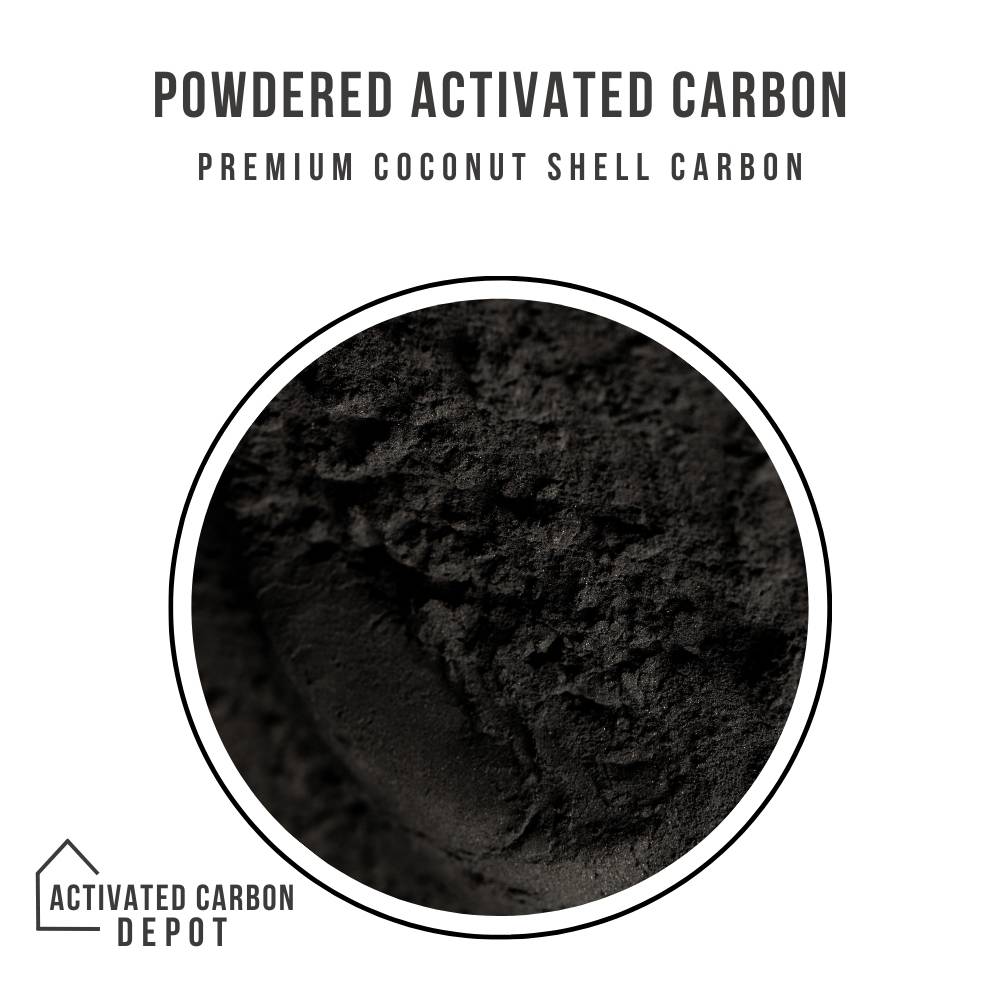

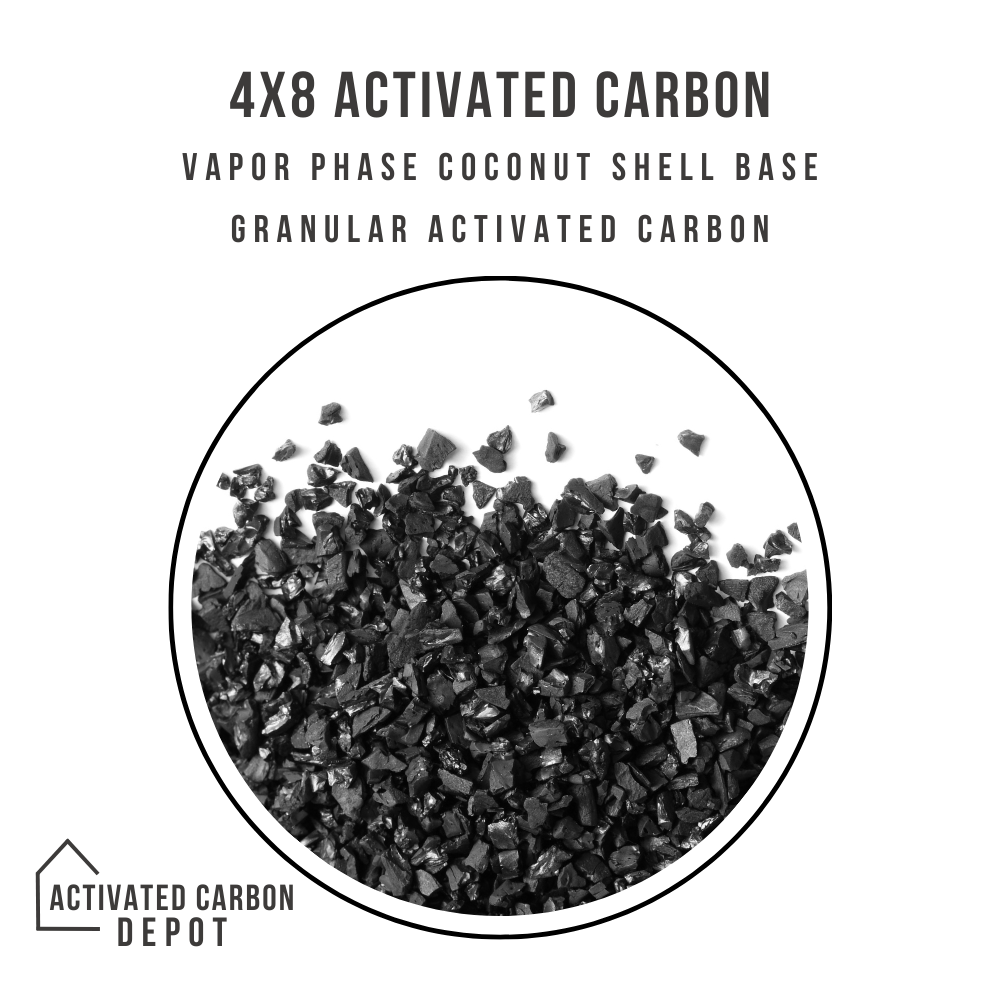

- Granular Activated Carbon (GAC): Ideal for large-scale filtration systems, GAC is effective in removing a wide range of impurities.

- Powdered Activated Carbon (PAC): Used for batch treatments, PAC is highly versatile and efficient.

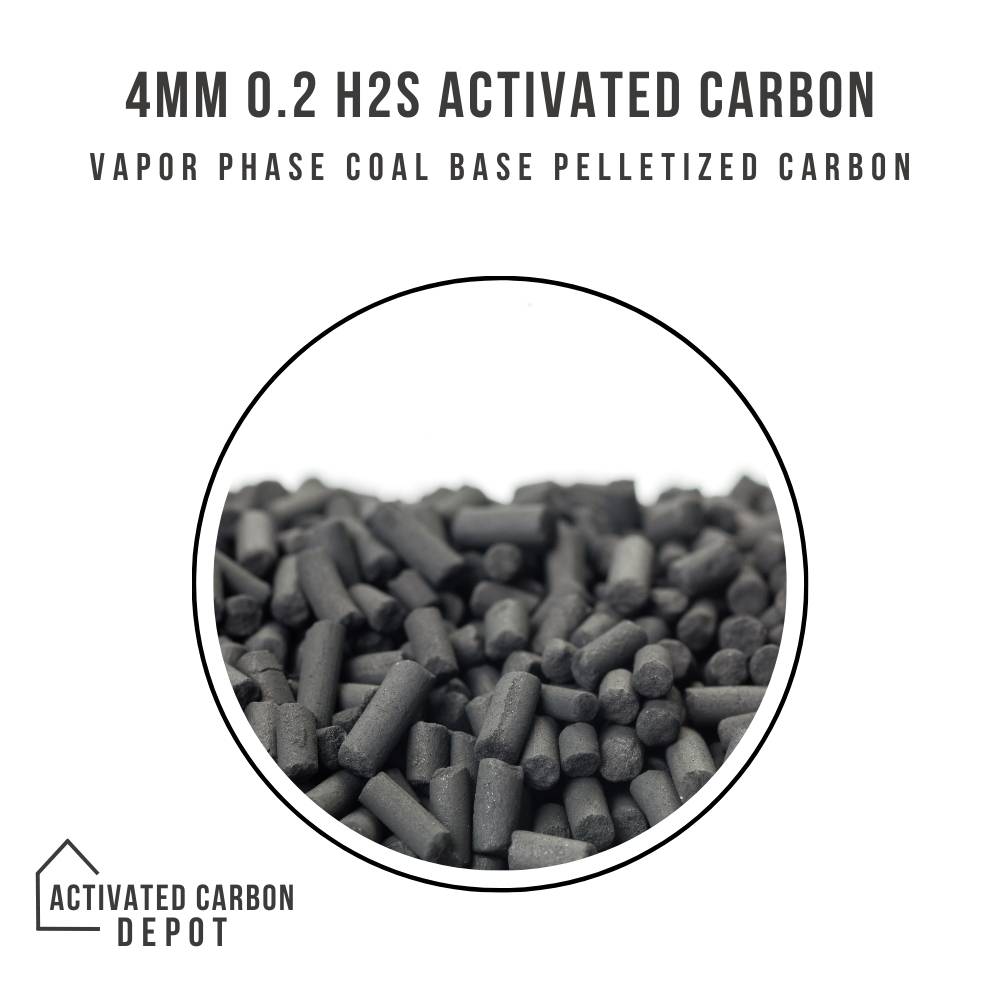

- Specialty Activated Carbon: Impregnated or chemically enhanced carbons can target specific contaminants.

Key factors to consider when selecting activated carbon include pore size distribution, surface area, and the quality of the raw material used in production.

Benefits of Using Activated Carbon in Distilleries

Activated carbon offers numerous advantages for distilleries:

- Enhanced Product Quality: By removing impurities and off-flavors, it ensures a superior tasting spirit.

- Consistency: Activated carbon helps maintain consistent quality across batches, which is crucial for brand reputation.

- Cost-Effective: Its high adsorption capacity allows for efficient use, reducing waste and operational costs.

- Eco-Friendly: Many types of activated carbon can be reactivated and reused, promoting sustainability.

- Regulatory Compliance: Using activated carbon can help meet industry standards and regulations for product purity.

Practical Tips for Using Activated Carbon in Distilleries

- Dosage: Start with small quantities and gradually adjust based on results. Overuse can strip desirable flavors from the spirit.

- Contact Time: Allow sufficient time for the activated carbon to interact with the spirit or water to achieve optimal results.

- Filtration: Use fine filters to prevent carbon particles from entering the final product.

- Replacement: Regularly replace or regenerate activated carbon to maintain its effectiveness.

Innovations in Activated Carbon for Distilleries

Recent advancements in activated carbon technology have introduced new possibilities for distilleries:

- Custom-Tailored Carbons: Manufacturers now offer activated carbon tailored specifically for different types of spirits, such as vodka, whiskey, and rum.

- Nano-Enhanced Carbons: These provide even greater adsorption efficiency and precision.

- Sustainable Production: Activated carbon made from renewable sources like coconut shells aligns with eco-conscious business practices.

Successful Use of Activated Carbon in Distilleries

- Vodka Distilleries: Known for its purity, vodka benefits greatly from activated carbon filtration, which removes impurities that can affect its clean, neutral taste.

- Whiskey Production: Activated carbon refines the aging process by polishing the flavor profile and improving clarity.

- Rum Distilleries: By eliminating undesirable flavors and odors, activated carbon enhances the sweetness and complexity of rum.

Conclusion

Activated carbon is an indispensable tool for modern distilleries, ensuring the production of high-quality spirits that meet both consumer expectations and industry standards. Its ability to remove impurities, refine flavors, and enhance the overall drinking experience makes it a cornerstone of the distillation process. As technology advances, distilleries can expect even more innovative applications of activated carbon, helping them craft exceptional spirits with consistency and efficiency.