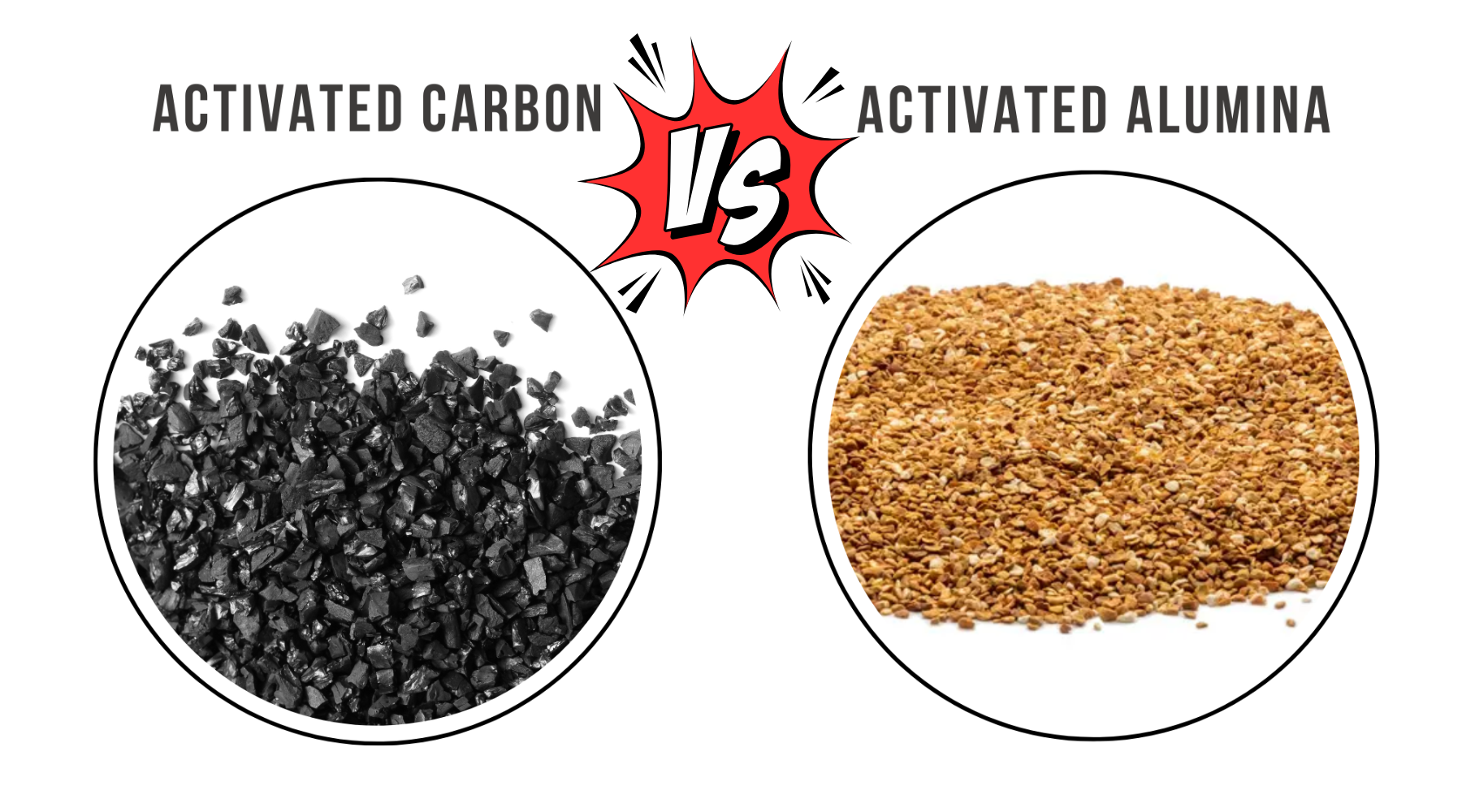

When it comes to water and air filtration, two of the most widely used filtration media are activated carbon and activated alumina. Both materials are highly effective in removing contaminants, but they function in different ways and are suited for different applications. This article provides an in-depth comparison of activated carbon and activated alumina, helping consumers and industries choose the right filtration medium for their needs.

What is Activated Carbon?

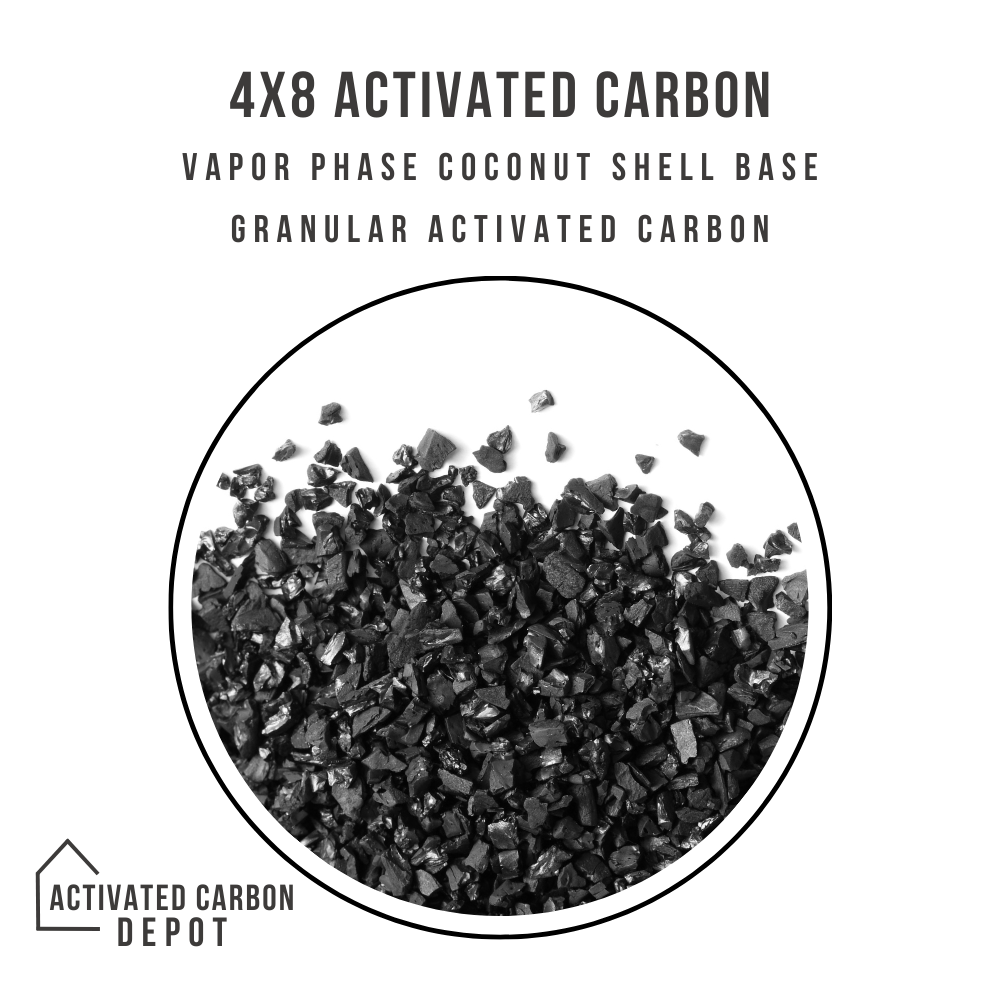

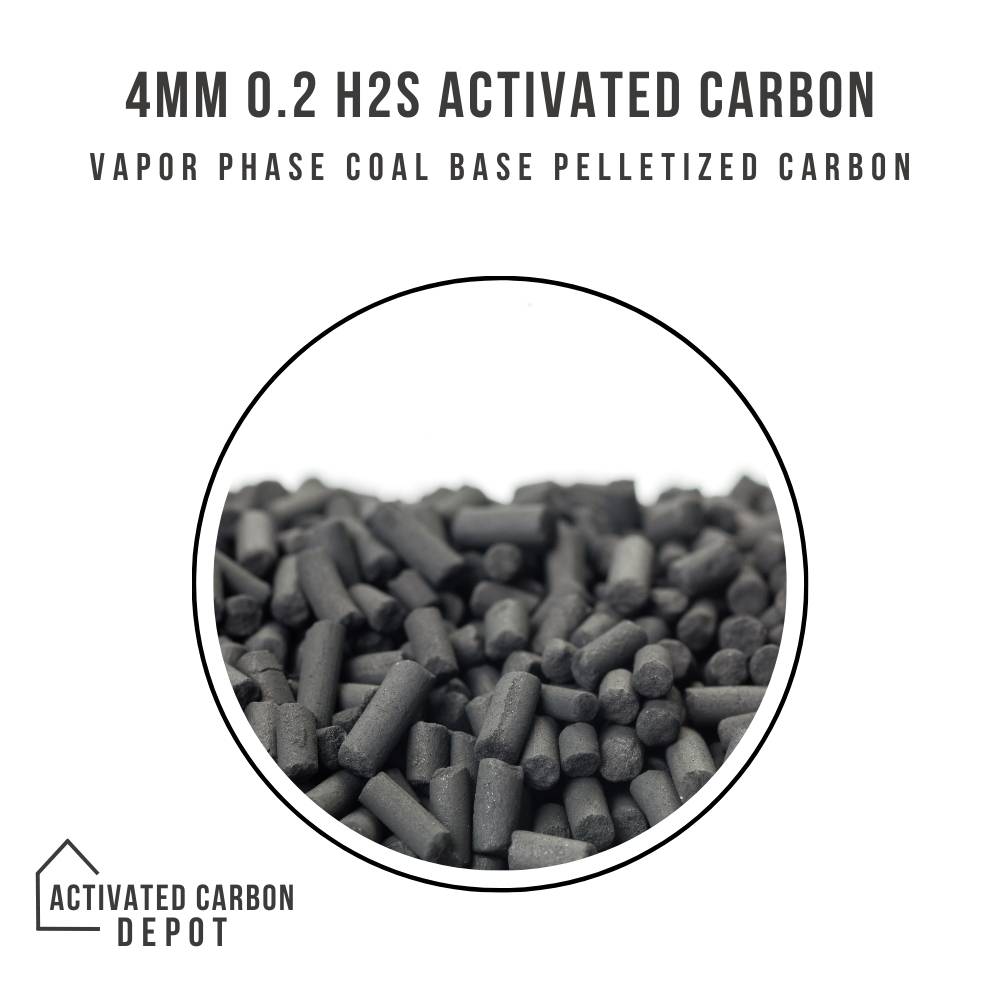

Activated carbon, also known as activated charcoal, is a highly porous form of carbon that is treated to have a large surface area. This material is primarily used for adsorption, a process where contaminants adhere to the surface of the carbon particles.

Key Properties of Activated Carbon:

-

High Adsorption Capacity: Can effectively remove organic compounds, chlorine, and volatile organic compounds (VOCs).

-

Common Sources: Derived from coconut shells, wood, and coal.

-

Best for: Removing odors, tastes, and certain chemicals from water and air.

Applications of Activated Carbon:

-

Water Filtration: Used in household and industrial water purification to remove chlorine, pesticides, and organic pollutants.

-

Air Purification: Employed in HVAC systems and air purifiers to trap odors, gases, and smoke.

-

Food and Beverage Industry: Removes impurities from products like sugar, edible oils, and alcoholic beverages.

What is Activated Alumina?

Activated alumina is a porous, high-surface-area form of aluminum oxide. Unlike activated carbon, it is primarily used for adsorption through chemical bonding, particularly for removing fluoride and heavy metals from water.

Key Properties of Activated Alumina:

-

Fluoride and Arsenic Removal: Highly effective in removing fluoride, arsenic, and selenium from water sources.

-

Regeneration Capability: Can be reused multiple times after proper treatment.

-

Best for: Adsorbing moisture, heavy metals, and specific chemicals from liquids and gases.

Applications of Activated Alumina:

-

Water Treatment: Used extensively in municipal and household water filtration systems to remove fluoride and arsenic.

-

Desiccant and Drying Agent: Helps in dehumidification by adsorbing moisture from compressed air and gases.

-

Industrial Applications: Used in petrochemical and oil refineries for purification processes.

Side-by-Side Comparison

| Feature | Activated Carbon | Activated Alumina |

|---|---|---|

| Primary Function | Adsorbs organic contaminants, chlorine, VOCs | Removes fluoride, arsenic, heavy metals |

| Best Used For | Water and air purification, odor removal | Water treatment, desiccation, industrial processes |

| Regeneration | Limited; requires replacement | Can be regenerated and reused |

| Material Source | Coconut shells, wood, coal | Aluminum oxide |

| Moisture Adsorption | Low | High (Used as a desiccant) |

| Chemical Treatment | Sometimes chemically enhanced for specific uses | Can be regenerated using heat or chemicals |

Choosing the Right Filtration Media

The choice between activated carbon and activated alumina depends on the specific filtration needs:

-

Use Activated Carbon If: You need to remove organic pollutants, chlorine, VOCs, and odors from water or air.

-

Use Activated Alumina If: Your primary concern is fluoride, arsenic, or heavy metal removal from water, or if you need a desiccant for industrial applications.

Both activated carbon and activated alumina are highly effective filtration media, but they serve different purposes. Activated carbon excels at removing organic compounds and odors, making it ideal for air and water purification. In contrast, activated alumina is specialized for removing fluoride, arsenic, and moisture, making it essential in water treatment and industrial drying applications. Understanding their differences will help users make informed decisions about which material best suits their needs.