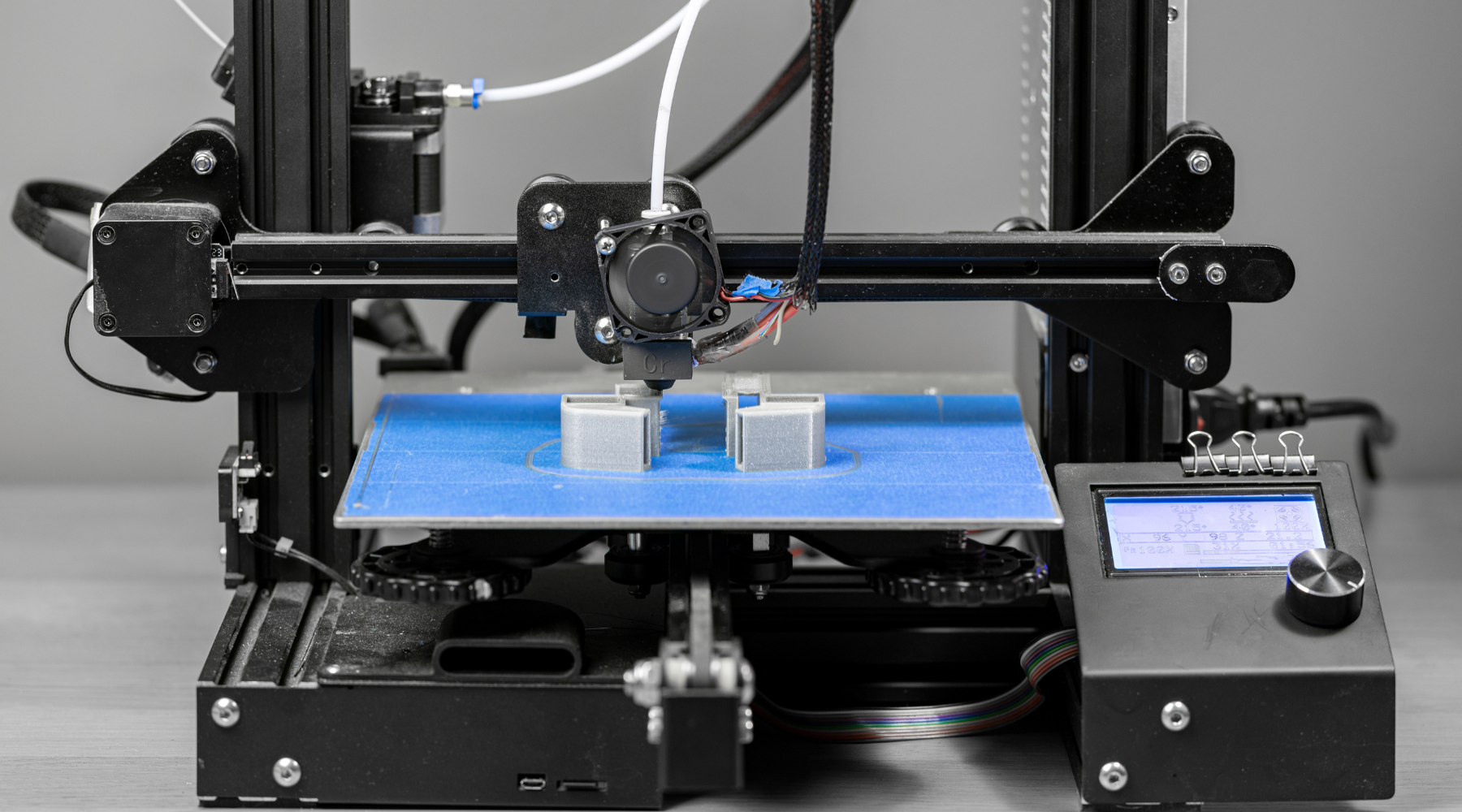

3D printing has transformed many industries, from manufacturing to healthcare, by making the creation of complex objects more accessible. However, the process of 3D printing, particularly when using materials like ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic Acid), often releases fumes and volatile organic compounds (VOCs) that can be harmful if inhaled over time. To address this issue, effective fume filtration is essential, and activated carbon proves to be a powerful solution for filtering these hazardous emissions, ensuring a safer and cleaner environment.

Understanding 3D Printer Fumes

During the 3D printing process, plastic filaments are melted and extruded to form objects, which can lead to the release of various fumes, including VOCs and ultrafine particles (UFPs). The type of filament used affects the composition of these emissions, which may include harmful substances such as styrene, formaldehyde, and other chemical byproducts. Long-term exposure to these fumes can cause health issues, ranging from respiratory irritation and headaches to more severe conditions.

How Activated Carbon Filters Work

Activated carbon is highly effective at adsorbing fumes, VOCs, and odors from the air. Its porous structure provides a large surface area that traps and holds onto chemical molecules, making it an ideal material for air filtration systems, especially in the context of filtering out the potentially harmful fumes produced by 3D printers.

Benefits of Using Activated Carbon for 3D Printer Fume Filtration

Activated carbon excels at removing VOCs from the air, significantly reducing the concentration of harmful chemicals in your workspace. This makes it safer to operate a 3D printer, even for extended periods. Additionally, activated carbon is highly effective in neutralizing the strong and unpleasant odors that can arise from 3D printing with certain materials, contributing to a more pleasant working environment.

The overall air quality in your 3D printing area can be greatly improved by using activated carbon filters, as they capture and remove fumes and particulates. This is particularly important in confined spaces or home environments where ventilation might be limited. Moreover, activated carbon filters are known for their durability and longevity, providing consistent fume filtration for extended periods when properly maintained.

SHOP NOW

Using our acid-free activated carbon for your 3D printer is essential for ensuring both the safety of your workspace and the longevity of your equipment. Unlike standard activated carbon, our acid-free variant is specially designed to effectively remove harmful VOCs and odors without the risk of releasing acidic byproducts that could corrode or damage sensitive components of your printer. This ensures not only a cleaner and healthier environment but also protects your 3D printer, allowing it to operate efficiently and with a longer lifespan.

How to Use Activated Carbon for 3D Printer Fume Filtration

To effectively use activated carbon for 3D printer fume filtration, start by selecting the right filter system. Many 3D printer enclosures or fume extraction systems come equipped with built-in activated carbon filters. If your setup doesn’t include this feature, consider investing in an external fume extractor with an activated carbon filter, ensuring it’s appropriately sized for your printer and the volume of air it needs to process.

Position the activated carbon filter close to the source of the fumes, ideally where the fumes are generated, to maximize its effectiveness by capturing emissions before they can disperse throughout the room. Regular maintenance is crucial, as the activated carbon in the filter will eventually become saturated with captured fumes and lose its effectiveness. Regularly check and replace the filters according to the manufacturer’s recommendations, which may be necessary every few months, depending on your printing frequency.

While activated carbon filters are highly effective, it’s also beneficial to ensure your workspace is well-ventilated. Combining filtration with natural or mechanical ventilation can help maintain optimal air quality. Additionally, using an air quality monitor to track VOC levels in your workspace can provide insights into when it’s time to replace the filter or adjust your ventilation setup.

Conclusion to Activated Carbon for 3D Printer Fume Filtration

Activated carbon is a critical component of a safe and effective fume filtration system for 3D printing. By capturing and neutralizing harmful VOCs and odors, activated carbon filters help protect your health and improve the air quality in your printing environment. Whether you’re a hobbyist or a professional, incorporating activated carbon fume filtration into your 3D printing setup is a wise investment in your safety and the quality of your work.